Introducing your Smart New Lab Assistant

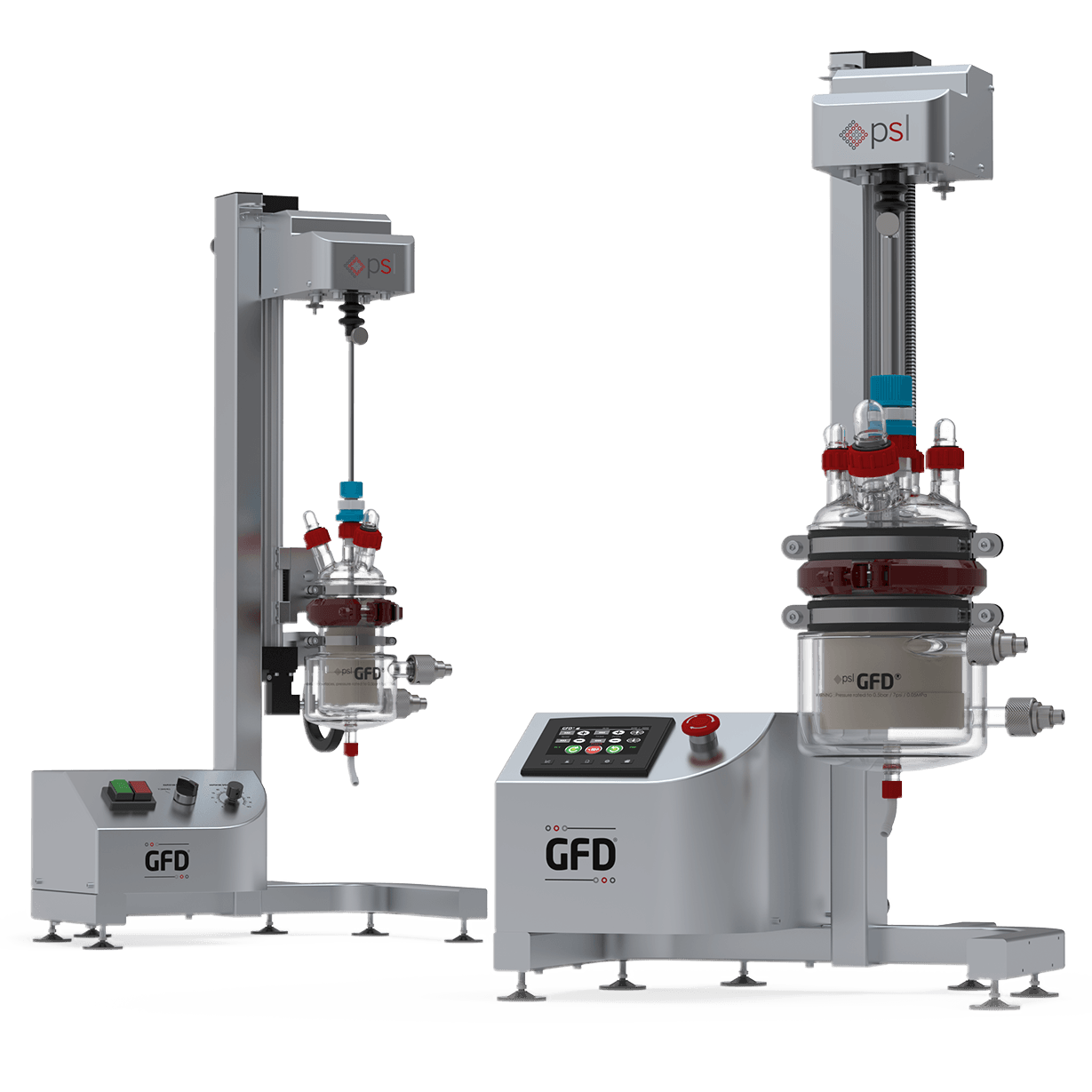

The GFD®Lab is a benchtop Agitated Nutsche Filter Dryer (ANFD) that efficiently performs laboratory solid-liquid separation processes. It is a miniature version of a production filter-dryer, allowing effective filtration and drying with the same reliability and benefits as full size PSL ANFD filter dryers.

It is designed to overcome well-known production challenges faced by manufacturers when using traditional production methods such as Büchner filtration and oven tray-drying and is the ideal technology to successfully complete scale-up and scale-down activities and to obtain predictive performance results.

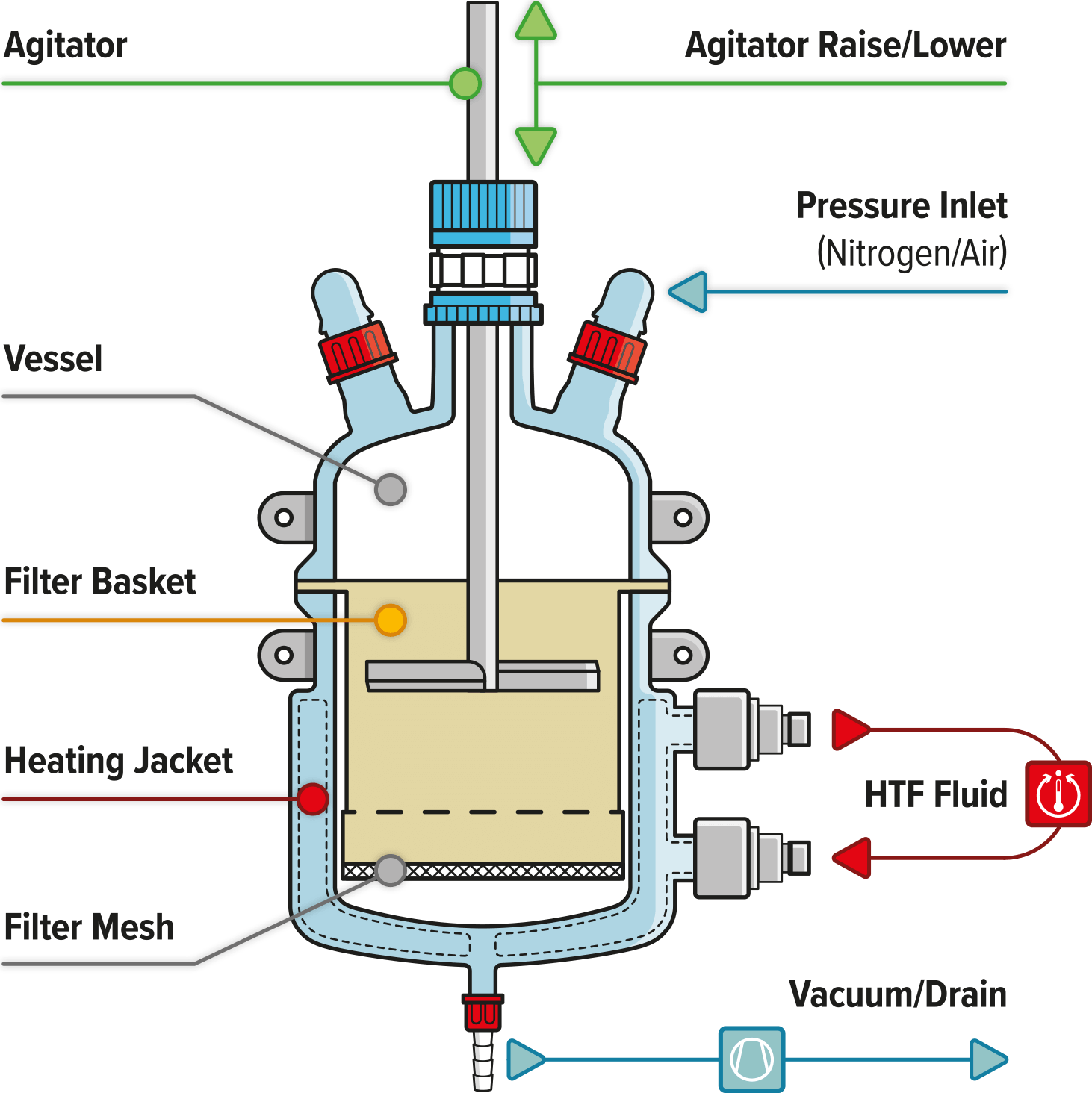

The GFD®Lab consists of an agitated vessel designed to work under vacuum and under pressure. The vessel can be made of either glass, stainless steel or Alloy-22 and has a heated jacket for efficient drying. Solid-liquid separation is performed within its unique filtration basket, which can be removed to ease and maximise product collection.

The GFD®Lab nutsche filter dryer is serving research institutes, laboratories, universities and companies from a wide range of industries. The technology is assisting scientists and process engineers to innovate and optimise their unique processes, worldwide.

Features and Benefits

Combined Filtration and Drying

The GFD®Lab is an all-in-one filter dryer designed to comply with Good Laboratory Practices (GLP) for regulated research and development activities. It allows process developers and manufacturers to complete through a wide range of processes in one single system:

Unrivalled Product Recovery

At PSL, we understand your product is valuable. Therefore, maximising your product yield to remain competitive in your sector is vital.

The core features of the GFD®Lab nutsche filter dryer are designed to address this crucial requirement. Upon process completion, your product batch can be easily collected by simply removing the unique filtration basket from the GFD®Lab vessel.

Additionally, the GFD®Lab basket is designed to allow quick and easy changeover of filtration meshes with various pore-sizes and materials (Polypropylene, PTFE, 316LSS, Alloy 22, etc.), hence facilitating multi-product applications.

Flexible Modular Design

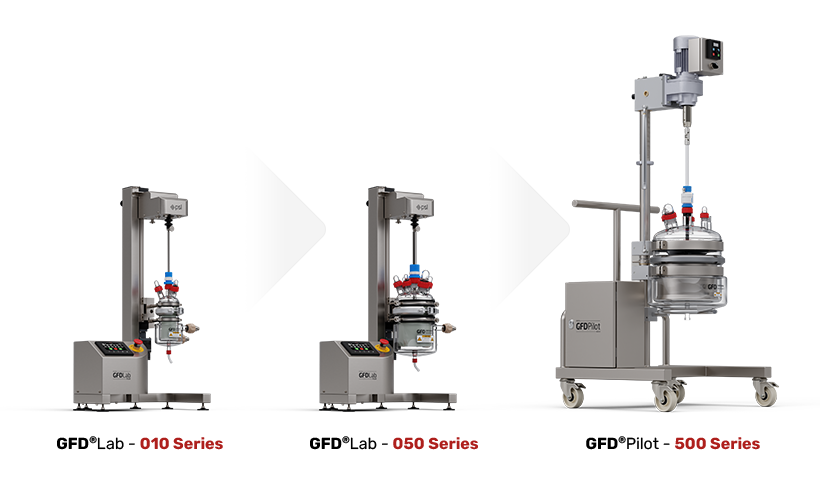

The GFD®Lab is an innovative agitated nutsche filter dryer with a modular design that enables end-users to interchange vessels sizes from the 010 and 050 series without the need to use a different base frame.

To further enhance production flexibility, the base frame of each GFD®Lab model is also compatible with all available vessel materials (i.e. borosilicate glass, 316LSS, Alloy 22)

GFD®Lab PLUS, Your Fast-Lane to Production

Due to its unique modular design, it is possible to upgrade the standard GFD®Lab Filter Dryer into a GFD®Lab PLUS model by simply retrofitting a new base frame to the existing vessel. By opting for this upgrade, the additional features allow you to speed-up development activities by automating the controls of your GFD®Lab.

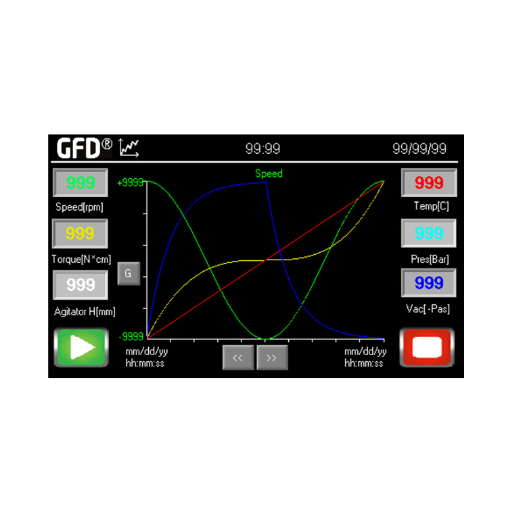

Batch Reproducibility, at the Touch of a Button

The GFD®Lab PLUS allows users to build bespoke process sequences and optimise process recipes to suit particular process applications.

Production can start at a touch of a button and pre-designed recipes can be initiated with your preferred process parameters (e.g. pressure/vacuum, agitator speed/torque, temperature, duration), thus maximising batch-after-batch reproduction while minimising human error.

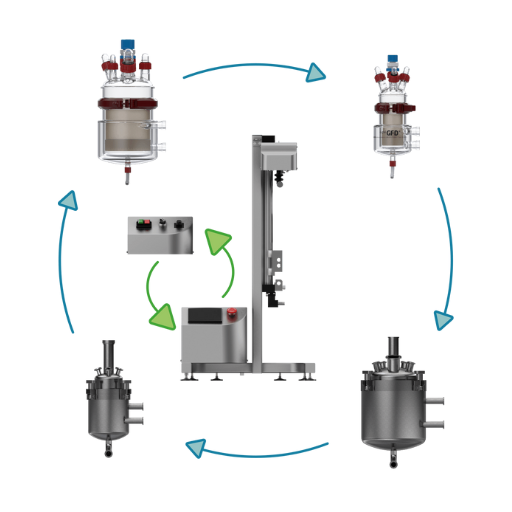

Predictive Scale-up

Selecting the right process technology at R&D stage is crucial to ensure ultimate scale-up success. PSL’s GFD® Nutsche Filter Dryers are designed to streamline scale-up development from early R&D activities with the GFD®Lab, up to GLP batches and Pilot Plant Production using the GFD®Pilot.

It is perfectly suited to complete scale-up and scale-down studies as it helps maintain, at every scale, your key process objectives (e.g. product quality, product yield, batch consistency, etc.) and key production parameters (e.g. filtration time, washing time, drying time, etc.).

Be Containment-Ready with the GFD® Filterbox

Being one of the early pioneers of containment technology, PSL has developed the unique FilterBox isolator range which can successfully accommodate every GFD®Lab vessel size (010, 050 and 500 series).

By opting for a GFD®Lab FilterBox, operators are safe-guarded from the most toxic/potent compounds and that your product is protected from production environments.

010 Series

010 Series 050 Series

050 Series