Welcome to Powder Systems:Solid Liquid Separation Experts

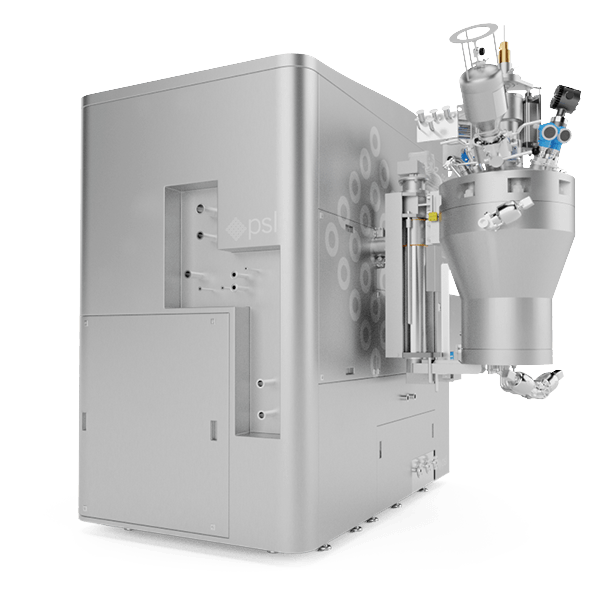

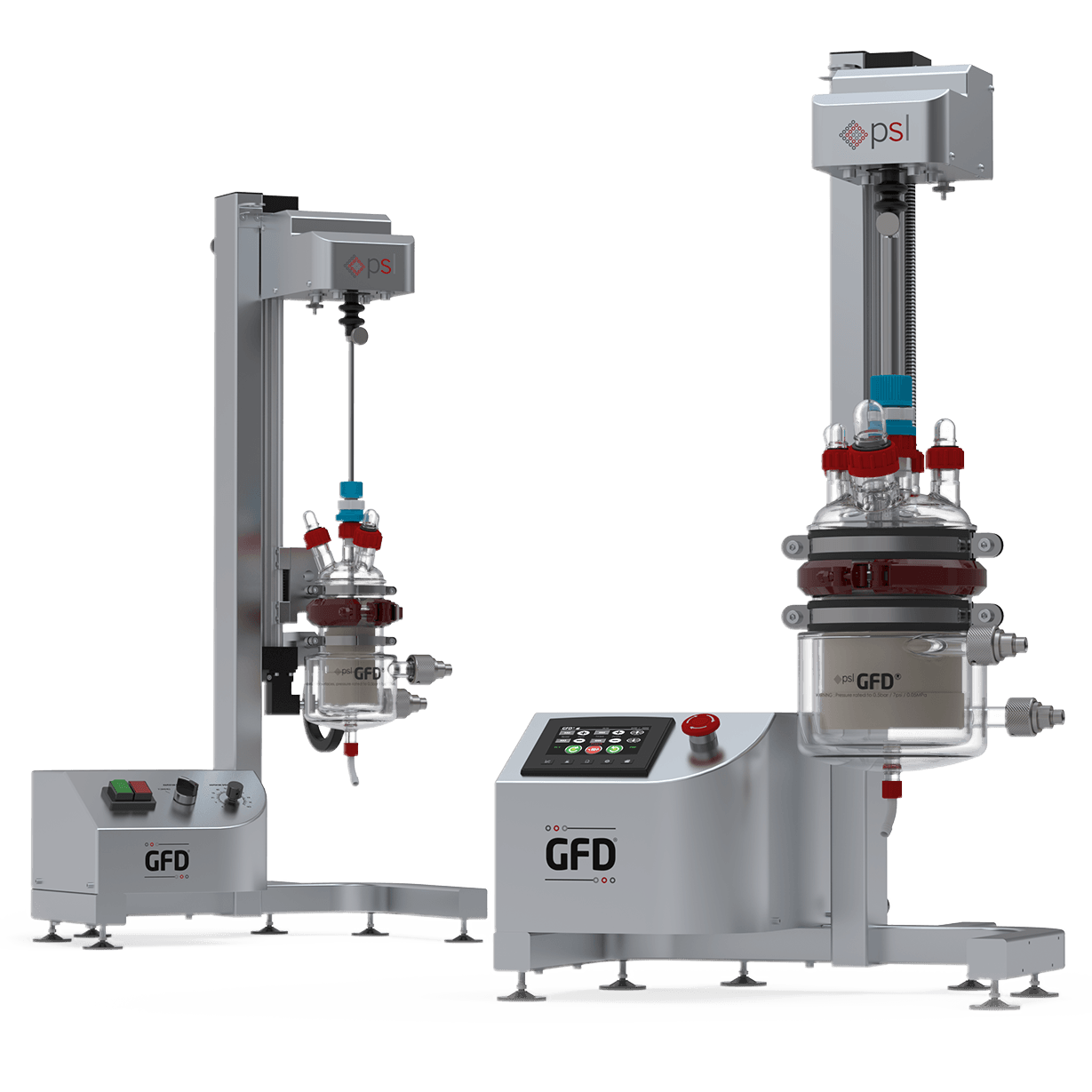

Recognised for our expertise in pharmaceutical and chemical processing, Powder Systems Limited (PSL) provides a full range of solid liquid separation solutions for filtration, drying, and processing from research and development activities up to larger commercial production scale.

Quality and innovation are central to everything we do. We are proud of our award-winning track record and have been working with industry partners for over 35 years.

We support our clients by developing solutions to overcome challenging manufacturing processes and provide first-class aftercare services.

Taking your process further, together

Our Solutions

PSL’s process understanding is fundamental to our success in providing advanced filtration and drying solutions, along with cutting-edge technology for microsphere refinement.

Take a look at our areas of expertise.

Our Services

Aftercare Services – PSL Serve™

PSL Serve is our dedicated customer care, on-site service and spares team. As technical specialists we are here to aid the smooth installation of new equipment, along with servicing and maintenance of existing PSL equipment and along with providing spare parts, as required.

Latest News from PSL

New Partnership Announcement with Spinco

PSL is delighted to announce our new distribution partnership with Spinco Biotech, offering our innovative filtration and drying technology throughout India.

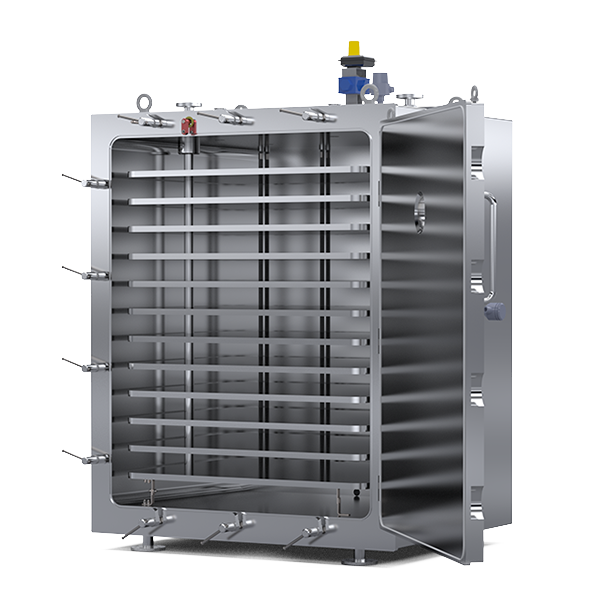

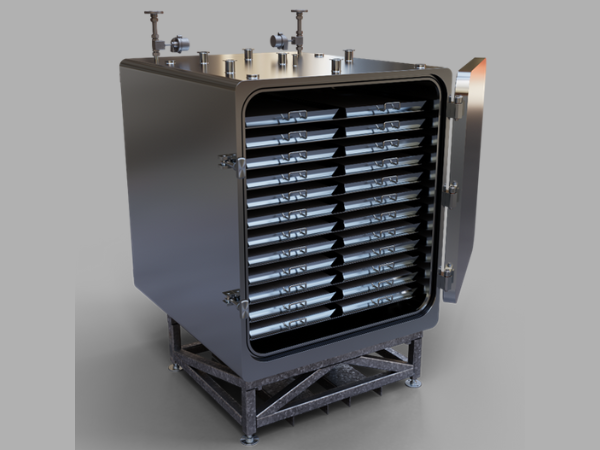

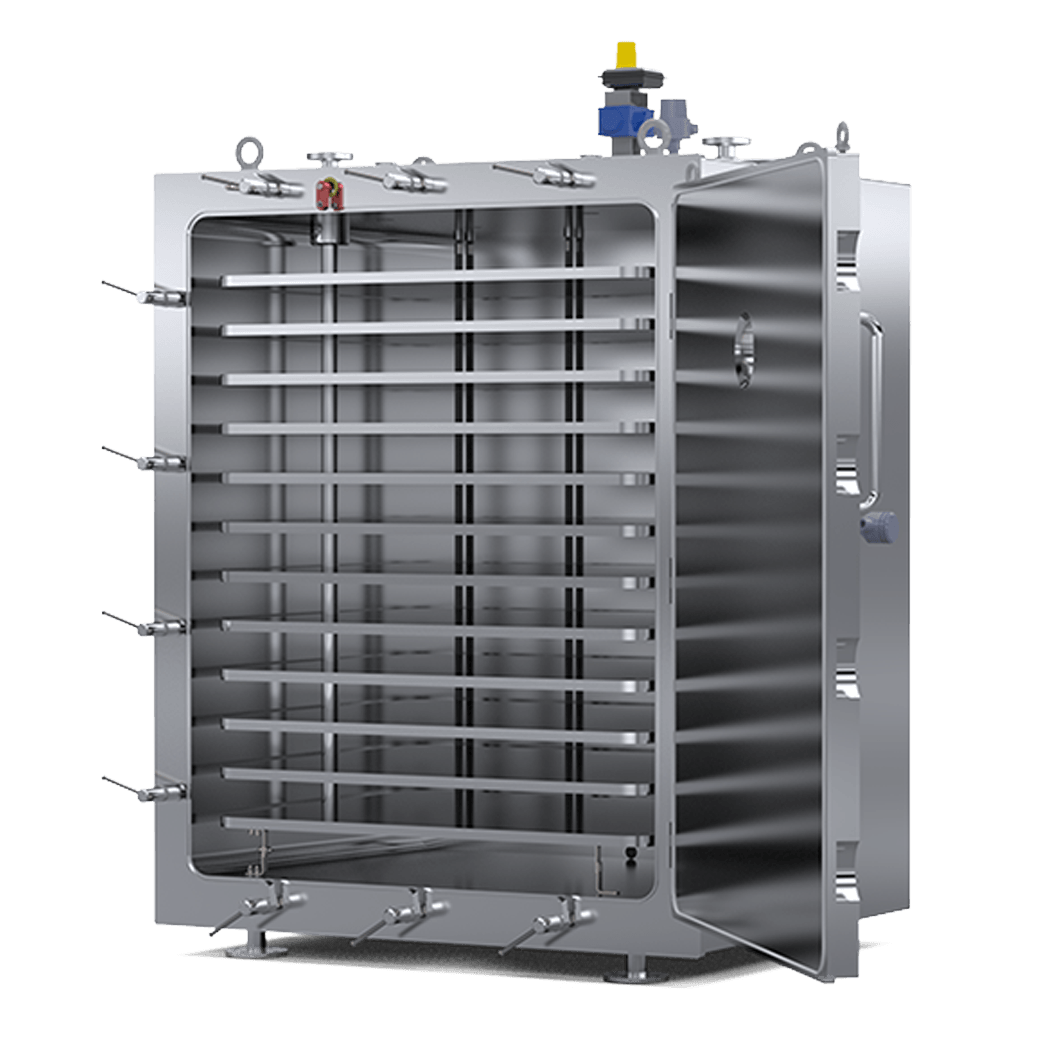

Why Direct Heating Trays are important in Pharmaceutical Manufacturing

Let's explore the working principles of direct heating trays and how they can safeguard product quality by optimising heat transfer mechanisms.

Key Features of a Solid-Liquid Filtration Vessel

Every part of a solid-liquid filtration system plays a key role in ensuring product safety, quality, and compliance. This article will highlight the importance of the solid-liquid filtration vessel, including key features that elevate performance.

Multi-Industry Process Expertise

As a recognised global life-science solution provider, PSL has considerable experience in working with key stakeholders in a wide range of technology-intensive industries. Our highly skilled engineering team collaborate with our clients and adapt to their needs to achieve successful outcomes, every time.