Accelerating your Success in Commercial Production

Everyday our technology is assisting hundreds of pilot and production facilities around the world to reliably manufacture and bring their products to the market faster. PSL Agitated Nutsche Filter Dryers (ANFD) are being used in a wide range of industries such as pharmaceuticals, fine chemicals and precious metals.

Our ANFD Filter Dryer production systems were developed to efficiently wash and isolate solids in the most complex chemical synthesis processes and challenging production environments. Our solutions are designed to overcome well-known challenges faced by manufacturers when using traditional production methods, such as Büchner filtration and oven tray-drying.

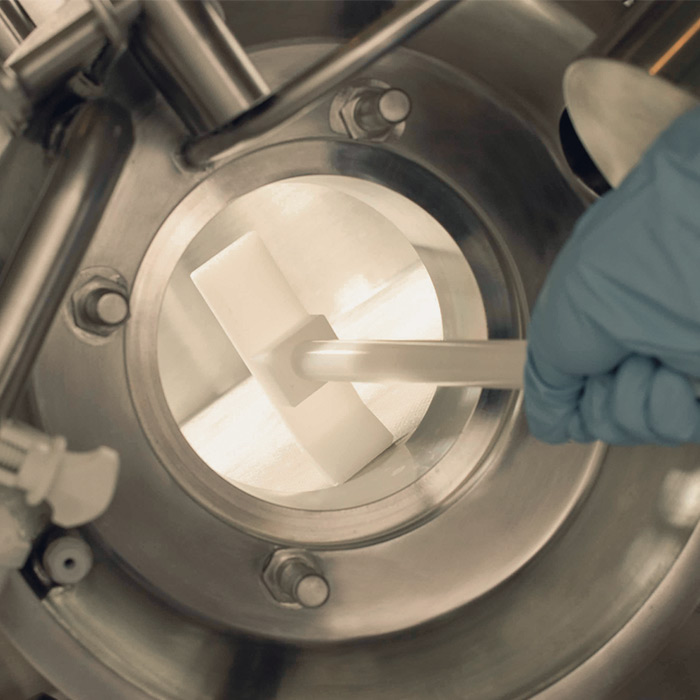

Each of our filter dryers consists of an agitated vessel designed to work under vacuum and under pressure. The vessel can be made of either stainless steel or alloy 22 and can be coated with specific materials such as PFA (perfluoroalkoxy alkane). It is also equipped with a heated jacket and heated agitator for efficient product drying and mixing.

Features and Benefits

Combined Filtration and Drying

PSL’s Agitated Nutsche Filter Dryers are an all-in-one piece of equipment designed to comply with Good Manufacturing Practices (GMP) for regulated development and production activities. They allow process developers and manufacturers to complete a wide range of processes into one single system

CGMP Compliance, Delivered

PSL’s strength lies in our comprehensive knowledge of the GMP regulations combined with our practical experience and knowledge of a wide range of manufacturing workflows.

Our PSL filter-dryers provide optimum levels of safety and quality and can be manufactured to comply with various industry practices (cGMP, GAMP, etc.), directives (ATEX, etc.), regulations (21 CFR Part 11, etc.) and initiatives (PAT, etc.) from industry regulators such as the FDA.

Be Containment-Ready

Over the last three decades PSL has earned the trust of our industry partners by delivering precision-built containment solutions to protect the health of their workforce.

Numerous industrial filtration and drying processes require to integrate containment technology in order to protect operators from highly toxic compounds and/or to protect sensitive products from a harmful production environment.

Our high containment systems guarantee operator protection and operate under negative pressure HEPA-filtered atmosphere. PSL isolators have been used globally to process highly potent compounds requiring extremely low Occupational Exposure Limit (OEL) such as 20ng/m3. These compounds can include High Potency Active Pharmaceutical Ingredients (HPAPI), cytotoxic and other hazardous substances.

Our containment solutions adapt to individual company needs either through rigid or flexible/disposable containment solutions.

PSL gloveboxes can be manufactured to comply with industry practices (cGMP, GAMP, etc.), directives (ATEX, etc.), regulations (21 CFR Part 11, etc.) and initiatives (PAT, etc.).

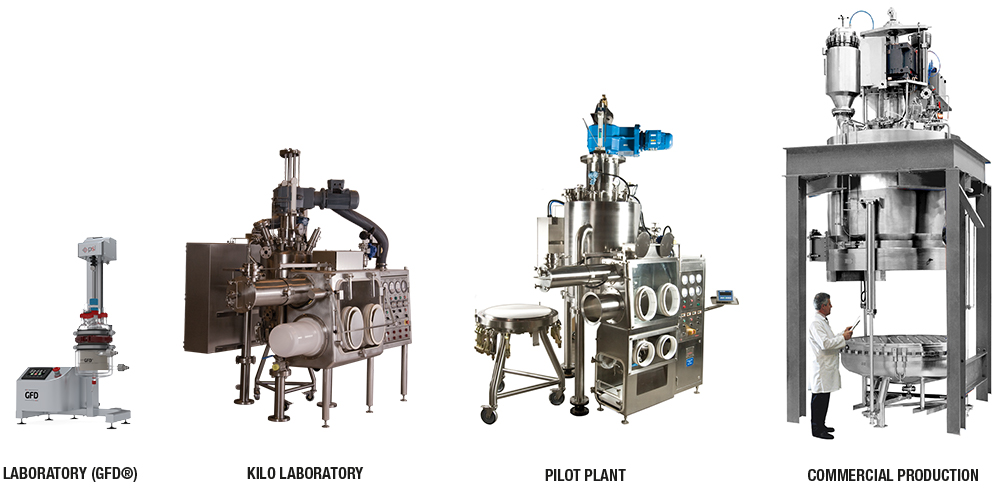

Predictive Scale-Up

At Powder Systems, we understand that selecting the right processing technology is critical to scale-up your process and ensure your ultimate production success.

Our established filtration and drying range is globally recognised to streamline the most complex scale-up process developments, from early R&D activities to GLP batches, pilot plant and ultimately GMP commercial production.

Our filter-dryer portfolio will allow you to perform scale-up and scale-down studies and maintain – at every scale – your various process objectives (e.g. product quality, product yield, batch consistency, etc.) and production parameters (e.g. filtration time, washing time, drying time, etc.).

Maximising Your Competitiveness

At PSL, we understand that your product is extremely valuable and that you must maximize your production yield in order to remain competitive in your market. The core features of our filter-dryers were designed keeping this crucial requirement in mind.

Upon process completion inside a PSL nutsche filter dryer, your valuable product can be recovered very simply by utilising the PSL agitator to automate the discharge process. Subsequently, the remainder of your batch – also called product heel – can be collected following the ‘’Direct Heel Recovery’’ method originally pioneered by PSL in the industry several decades ago.

This method has proven to be the most efficient for high yield productivity and it consists of manually raking the product heel into a PSL high containment off-loading glovebox (ergonomically designed and integrated by PSL). Thus ensuring a full product recovery under safe conditions for your operators, product and environment.