The GFD®Pilot Agitated Nutsche Filter Dryer (ANFD) is the perfect intermediary between PSL’s laboratory and commercial manufacturing filter dryers. It can be used for small batch production but is more commonly used as the natural progression from smaller scale R&D activities carried out in the laboratory, offering proof of concept processing and feasibility capability.

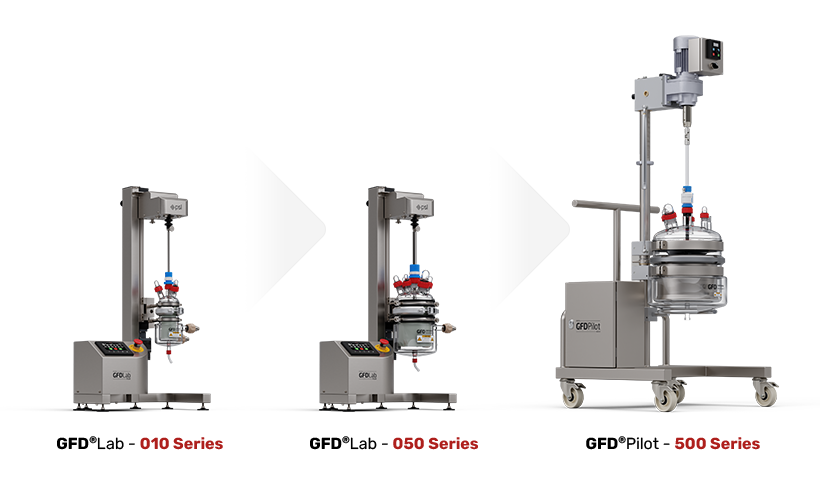

Scaling up the GFD® Family

PSL’s GFD® ANFDs are highly regarded for their efficiency, reliability and performance. They are used for solid-liquid separation activities primarily in the pharmaceutical and fine chemicals industries under the name GFD®Lab. There have always been different sizes and configurations within the GFD® range – the 010, 050 and 500 series. The smaller sizes were specifically adapted for Lab use with features including benchtop design, compact, ergonomic.

The 500 series offers operational volumes/capacities that are often classed as as Pilot experiments from a business strategy point of view. It was natural to reposition the 500 series under the name GFD®Pilot to help highlight the key features and benefits that differentiate it from being a benchtop ANFD and address requirements that only start to matter at these larger scales.

As with the GFD®Lab, the GFD®Pilot comprises an agitated vessel engineered to operate under vacuum and under pressure. The vessel is manufactured from Borosilicate 3.3 glass, 316L Stainless Steel or Alloy 22 and has a heated jacket for efficient drying. Solid-liquid separation is carried out within the filtration basket which is removable to maximise product recovery.

Key Features of the GFD®Pilot

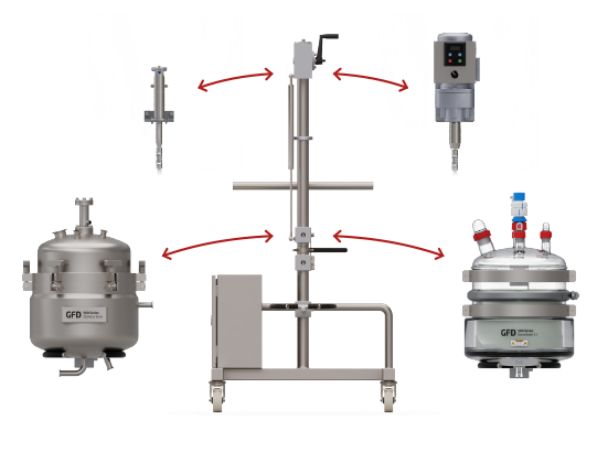

Combined Filtration & Drying in a Modular Design

The GFD®Pilot is an all-in-one filter dryer that complies with Good Laboratory Practices (GLP). It performs multiple processes in a single, standardised system. The way it is designed means the base frame and motor are compatible with all relevant vessel materials, offering a simple, fit-for-purpose solution. The floor standing mobile frame design also allows for a seamless integration into factory environments where various processing streams exist. Here, the GFD®Pilot becomes the perfect solution for use in multiple locations, reducing the overall capital expenditure/equipment investment otherwise required.

Hazardous Area Compliant

When operating at the volumes available with the GFD®Pilot, organic solvents used in chemical and pharmaceutical processes can result in hazardous area considerations. PSL offer solutions for such circumstances which have ATEX and NFPA certification.

Containment Ready

To ensure operators are safe-guarded from toxic/potent compounds and the product is protected from production environments, the GFD®Pilot can integrate with packages from third-party containment providers. PSL also offers its own GFD®FilterBox isolator range to accommodate all the GFD®Pilot vessel types.

Interested in knowing more?

To learn more about GFD®Pilot visit the product page and download the new brochure. For details of all filter dryer systems available from PSL, click here.