Our FAQ page identifies the most common questions our Sales, Technical and Customer Care teams receive. The answers are categorised by product range for quick access.

If you have a question that is not included on this page, please contact us and we will assist you with your query.

Click the FAQ links to reach the topics that interest you

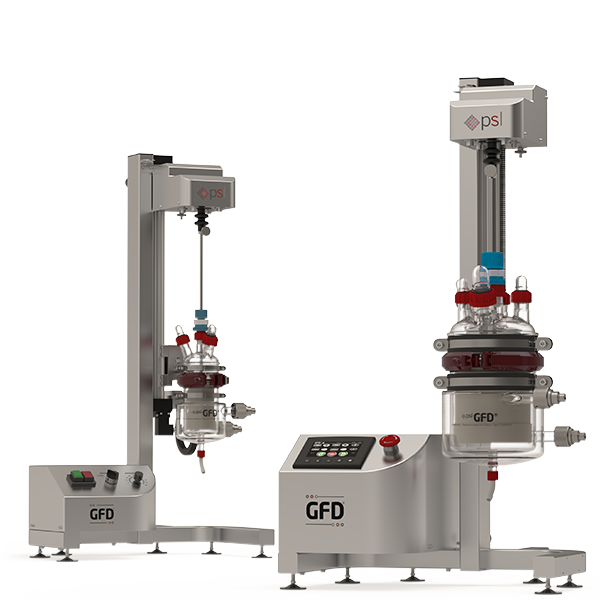

Selecting the right GFD®Lab vessel size is achieved by looking at the expected cake volumes from the process and matching this to the operating cake volume range of the vessel sizes.

The GFD®Lab Nutsche Filter Dryer is a versatile piece of equipment suited to Research & Development, often resulting in it being used with several processes/products. When selecting equipment it is important to verify the compatibility of the materials of construction (MoC) with the process.

It is recommended that the following checks are undertaken.

- Compatibility against expected solvent(s) present in liquid and vapour phases so the sealing elements (O-rings, gaskets) are a suitable MoC

- Compatibility against solid materials in case of corrosive properties which may result in the use of particular types of metal (e.g. Alloy C22 over 316L Stainless Steel)

- Temperature and pressure requirements during the process against the limits of an MoC (e.g. Metallic vessels over Glass vessels in case of higher pressures)

PSL always strive to support our partners by offering a range of options relating to our products.

If we are unable to accommodate particular requirements, the design of the GFD®Lab basket does allow third-party mesh to be used only if it is cut to the correct dimensions and is a suitable thickness (approximately up to 2mm).

Automation, which is only available on the GFD®Lab PLUS, is carried out via a sequence configurator. Each sequence can contain up to 4 process steps. For each step, the user can program different parameters: agitator speed, agitator height, agitator direction, torque limit, temperature, pressure and timer.

The GFD®LabPlus can also save a sequence to an SD Card. This “recipe” can be recalled at a later stage. Up to 99 recipes can be saved to the system at any one time.

Process data capturing automation is only available on the GFD®Lab PLUS. The agitator speed, agitator height, agitator direction, torque, temperature* and pressure* can all be monitored. (* The latter only if optional instruments are purchased).

The data is stored locally on the GFD® and can be exported to a USB stick mounted at the back of the control box. The data is exported in .csv format.

The main benefit of a Nutsche Filter Dryer over Buchner filtration is that the equipment can also dry the product. If we compare only the filtration aspects, the Nutsche Filter Dryer is superior in many ways such as the provision of a fully sealed/closed vessel. Nutsche Filter Dryers also provide vacuum filtration from below the mesh like Buchner Filters, but also pressure filtration from above the mesh. Pressure filtration allows much lower moisture content to be achieved.

Product washing is also more efficient using a Nutsche Filter Dryer. Gravity/displacement washes are carried out, as is possible with a Buchner Filter, but the agitator feature of a Nutsche Filter Dryer allows re-slurry washes to be performed, thus reducing the amount of solvent volume required and optimising the removal of impurities.

The main benefit of using a Nutsche Filter Dryer rather than a Tray Dryer is that dynamic drying can be achieved with the use of the rotating agitator.

Drying in static trays can lead to a crusting effect with the top surface drying more quickly than the middle of the cake. A Nutsche Filter Dryer overcomes this challenge by using the agitator in the “ploughing” direction to gently mix the product and provide a drying uniformity. Lastly, the agitator mixing will also be able to break down agglomerates to provide free-flowing powders.

The profile of the agitator blades is angled, thus they provide different functions depending on the direction of rotation. One direction will provide a smoothing effect, whilst the other provides ploughing/gentle mixing.

Smoothing is carried out to remove any cracks that might appear through the cake. If these cracks are not removed they act as preferential channels for product washing solvents or gas during pressure filtration, thus hindering their efficiency.

Although filter dryer agitators can be adjusted in height, there is always a clearance with the mesh even in the lowest position. This volume of product is referred to as the heel. This heel can either remain in the filter dryer and be further processed with the next batch or can be manually removed using raking tools through PSL’s containment discharge solutions.

A Nutsche Filter Dryer is usually dimensioned against the expected solid volume, also referred to as cake volume. The maximum cake volume is determined by the agitator stroke (i.e. raised to its maximum height) in order to smooth the top surface of the cake.

Various mesh types exist but we can distinguish two major ones. These are Filtration Cloth Mesh, in materials such as Polypropylene, PEEK, PTFE, etc. and Metallic Sintered Mesh (multi-layered), in similar materials as the filter dryer vessel (316L Stainless Steel or Alloy C22).

Both types come in various porosities in order to suit various particle size distributions. The choice of mesh usually depends on the process and product characteristics, but can also be driven by your organisation’s structure.

A filtration cloth mesh could be easier to use in a multi-product environment where it would be used as a consumable in order to limit time spent in equipment cleaning and validation.

Metallic mesh, which is more costly, filters elements that would be cleaned in situ, along with the equipment. It is used more frequently in a single product environment or when plastic contact parts are not acceptable as part of the process.

Solids can be discharged via a side discharge plug, located level with the filtration mesh to minimise any product retention, either:

– through an automatic discharge hatch (frequent for large equipment or for feeding by gravity to a lower floor for packing-off).

– into a discharge containment solution which requires manual handling; this can be via rigid gloveboxes or flexible/disposable glovebags.

Some processes require the product to be removed in a slurry form, which can be done through a slurry valve situated above the filter mesh.

PSL has over 30 years of experience in containment and our experts will guide you through the correct selection process. The solution will depend on various factors such as:

- the containment performance that the equipment must meet, usually driven by the OEL of the product(s) to be manufactured.

- the batch sizes and manual handling limitations. Containment solutions are not the same if only a single container is required compared to when multiple containers are necessary.

- the role of the Nutsche Filter Dryer within your process line. The containment approach will differ if it is the final step compared to if the product is to be transferred to further equipment downstream.

The containment transfer devices used can also differ – Rapid Transfer Port (RTP), Split Butterfly Valves (SBV), and Continuous Liner for example.

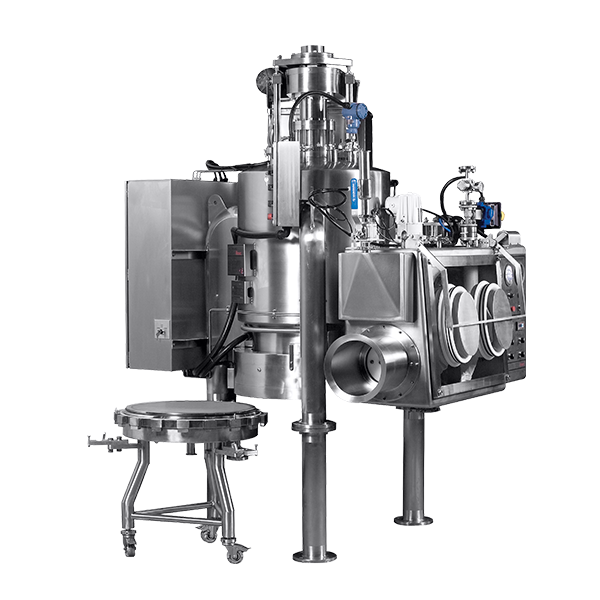

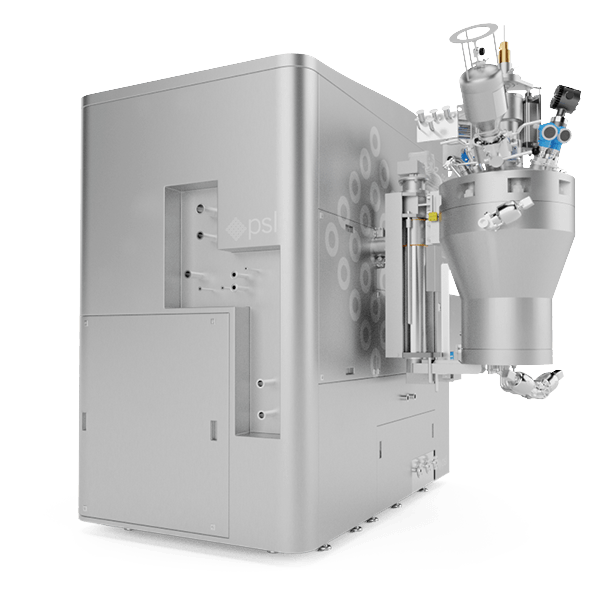

The MSR™ contains various engineered filtration areas that use filtering mesh. The mesh provides a cut-off point for removing undersized particles/debris. In order to achieve the correct porosity against your desired particle size distribution (PSD), filter mesh is interchangeable.

PSD stands for Particle Size Distribution. When considering polymeric formulations, they usually contain various sizes of microspheres in the end product. The difference in size helps create an adequate drug release profile over time.

Yes, the MSR™ MicroSphere Refiner platform allows for freeze-drying as a process option. Bulking agent (typically Mannitol) can be introduced into the vessel before performing a typical batch freeze-drying cycle. The agitator helps break the sublimated cake back into a free-flowing powder form.

No, this is not possible. The MSR™ has been developed to overcome the challenges of processing microspheres once they have been created, i.e. product washing, product drying, an efficient harvesting method, etc.

Various methods for creating microsphere do exist and PSL can guide you to industry partners for assistance with emulsification, coacervation, membrane emulsification, spray drying, etc.

The PSM contains all the relevant components required to provide full automation and precise control of the process parameters. Valves, Sterile Filters, Regulators, Various Transmitters (flow, temperature, pressure etc.), Steam Traps and the relevant Distribution Piping all integrate into the MSR™ software package.

For the Clinical Trial/Commercial range, the MSR™ Platform is a Plug & Play offer. You only need to connect your upstream process, a waste line and common utilities (electricity, compressed air, nitrogen, clean steam) and our Platform would take care of the rest via the PSM and Integrated Ancillaries (Vacuum Pump Skid, Temperature Control Unit).

We understand the importance of documentation and traceability when developing or producing pharmaceutical drugs. This is why the MSR™ platform includes all the requirements to support your organisation: full audit trail, redundant SCADA, batch reports,… under 21 CFR Part 11 Compliance.

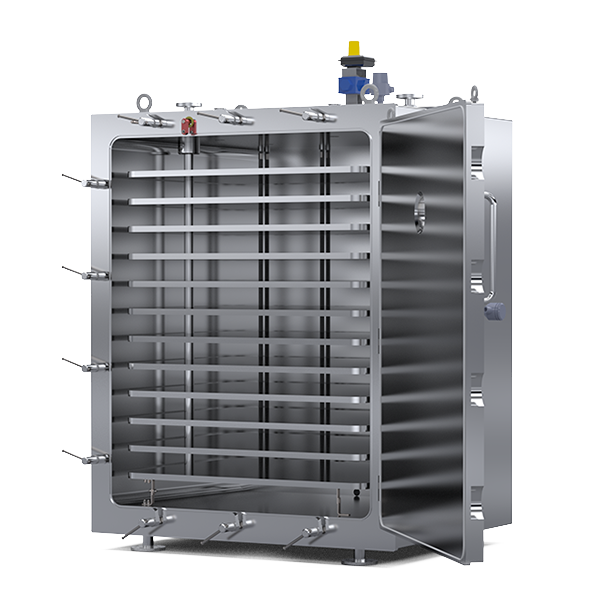

CakeStand™ Tray Dryers are very much a batch process as the product physically sits within the vacuum heated chamber for a certain amount of time before being removed.

The CakeStand™ Tray Dryer has been used for semi-continuous processes. If you use several units you can alternate by using one and starting the next one in desynchronisation.

A tray dryer is dimensioned by considering the useful shelf area (in m²) that will be required. Being a batch process, it will be important to know what is the volume of slurry/wet solids that need to be dried.

It will also be important to know what is the maximum thickness of product that your process can accommodate in the trays. As a rule of thumb, we don’t recommend going any higher than 50mm, but some products require limiting to thinner layers to have a performant drying.