PSL is regarded as a pioneer and world leader in the design of advanced containment systems for various industries such as pharmaceuticals, biotech, fine chemicals and chemicals. Our unique isolator range comprises of a number of containment solutions from laboratory R&D scale up to commercial production.

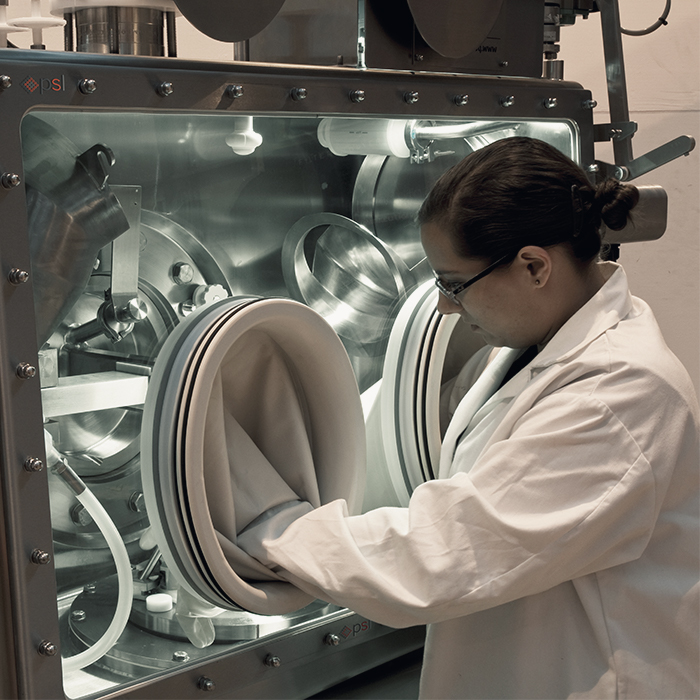

Safeguarding the Health of your Workforce

Over the last three decades PSL has been earning the trust of our industry partners by delivering precision-built containment solutions to protect the precious health of their workforce.

Our high containment systems guarantee operator protection and operate under negative pressure HEPA-filtered atmosphere. PSL isolators have been used globally to process highly potent compounds requiring extremely low Occupational Exposure Limit (OEL), such as 20ng/m3. These compounds can include High Potency Active Pharmaceutical Ingredients (HPAPI), cytotoxic and various hazardous substances.

Our PSL gloveboxes can be manufactured to comply with various industry practices (cGMP, GAMP, etc.), directives (ATEX, etc.), regulations (21 CFR Part 11, etc.) and initiatives (PAT, etc.) from industry regulators such as the FDA.

SAFEGUARDING THE HEALTH OF YOUR WORKFORCE

Over the last three decades PSL has been earning the trust of our industry partners by delivering precision-built containment solutions to protect the precious health of their workforce.

Our high containment systems guarantee operator protection and operate under negative pressure HEPA-filtered atmosphere. PSL isolators have been used globally to process highly potent compounds requiring extremely low Occupational Exposure Limit (OEL), such as 20ng/m3. These compounds can include High Potency Active Pharmaceutical Ingredients (HPAPI), cytotoxic and various hazardous substances.

Our PSL gloveboxes can be manufactured to comply with various industry practices (cGMP, GAMP, etc.), directives (ATEX, etc.), regulations (21 CFR Part 11, etc.) and initiatives (PAT, etc.) from industry regulators such as the FDA.

Protecting your Product Integrity

PSL has developed advanced aseptic solutions that operate under positive pressure to protect products and processes from external contamination and therefore maximise patient safety.

Our aseptic isolators are designed to offer quality assurance of product integrity by either providing single-pass turbulent flow or recirculated unidirectional airflow to achieve a GMP Class A / ISO 5 environment.

PROTECTING YOUR PRODUCT INTEGRITY

PSL has developed advanced aseptic solutions that operate under positive pressure to protect products and processes from external contamination and therefore maximise patient safety.

Our aseptic isolators are designed to offer quality assurance of product integrity by either providing single-pass turbulent flow or recirculated unidirectional airflow to achieve a GMP Class A / ISO 5 environment.

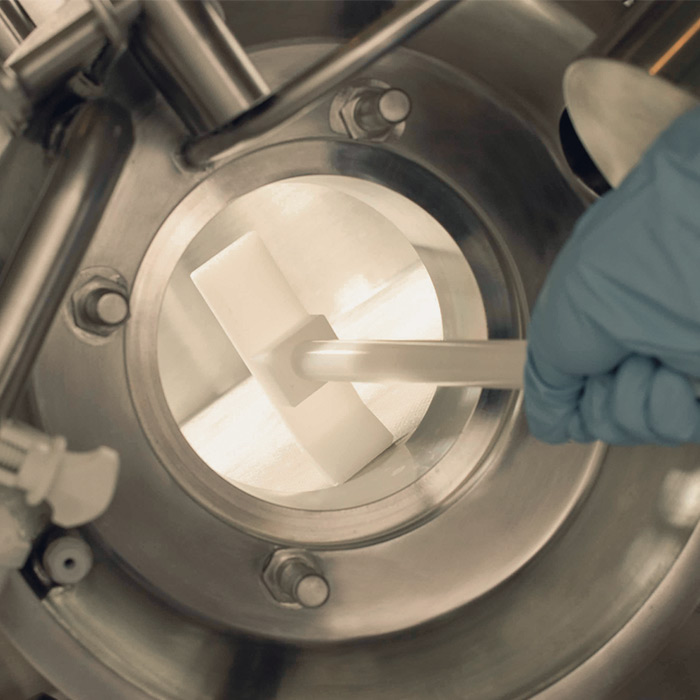

Unrivalled Process Integration Expertise

Being one of the global players in process filtration and drying technology, PSL has developed unique containment solutions to be integrated with its nutsche filter-dryer and tray-dryer ranges.

PSL containment systems can be integrated into complex synthesis processes to allow end-users to complete a large range of operations while being protected and maximizing product yield. These activities can include product sampling, product discharge and product milling.

UNRIVALLED PROCESS INTEGRATION EXPERTISE

Being one of the global players in process filtration and drying technology, PSL has developed unique containment solutions to be integrated with its nutsche filter-dryer and tray-dryer ranges.

PSL containment systems can be integrated into complex synthesis processes to allow end-users to complete a large range of operations while being protected and maximizing product yield. These activities can include product sampling, product discharge and product milling.

Industry Testimonials

Capsugel’s business demands high standards and this was no different when selecting a specialist containment company to partner in the development of the Xceloprotect™ isolator – a high containment solution for our Xcelodose® precision powder micro-dosing system. The need for a history of sector expertise, and demonstration of understanding and delivering bespoke designs, led us to PSL after a stringent vendor selection process.

The co-operation between PSL and Helsinn was a real success. The ergonometric, performances and fine-tuning of the containment equipment derived directly from the straight and fruitful communication skills between PSL and Helsinn management. Undoubtedly the most creative and innovative ideas came through long and positive conversations between the project managers of the respective companies.

From initial contact through to design, delivery, installation and qualification, I could not fault the service provided by PSL. The GFD filter box was ergonomically designed to be fit for purpose for our process making easy for operators to use. I would strongly recommend using PSL for any of your containment needs.